Countersunk holes are conical openings in materials for screws, ensuring flush alignment. They enhance structural integrity and provide smooth surfaces, critical in engineering and manufacturing. Using a countersunk hole dimensions chart ensures precise sizing, alignment, and material compatibility, preventing installation issues and material damage. Proper dimensions guarantee optimal fit and performance.

Definition and Purpose

A countersunk hole is a conical opening in a material, designed to accommodate a screw head, ensuring it sits flush with the surface. Its purpose is to provide a smooth finish and prevent protrusions, enhancing both aesthetics and functionality. The hole consists of a pilot hole for the screw shank and a countersink for the head. Properly sized countersunk holes are essential for secure fastening, stress distribution, and preventing material damage. They are widely used in engineering, construction, and manufacturing to achieve precise, reliable assemblies and maintain structural integrity.

Common Applications in Engineering

Countersunk holes are integral in various engineering applications, including aerospace, automotive, and construction; They are used in aircraft components for flush surfaces, reducing drag. In automotive manufacturing, countersunk holes ensure smooth finishes for interior and exterior parts. Construction applications rely on them for secure fastening in metal and wood. Additionally, electronics and furniture manufacturing utilize countersunk holes for sleek designs and durable assemblies. Their versatility ensures they are a critical feature in creating safe, efficient, and visually appealing structures across industries, adhering to precise dimensional standards for optimal performance.

Importance of Using a Dimensions Chart

A dimensions chart ensures accurate hole sizing, alignment, and material compatibility. It prevents installation errors and material damage, optimizing fit and performance while reducing production costs.

Ensuring Proper Fit and Alignment

Using a countersunk hole dimensions chart guarantees precise measurements for pilot hole diameter, countersink diameter, and angle. Proper fit ensures screws sit flush, preventing misalignment and material stress. Incorrect dimensions can lead to installation errors or damage. Gauges and depth measurements help verify accuracy. For example, an ANSI Metric M4 machine screw requires a pilot hole of 4.5 mm and a countersink diameter of 9.4 mm for a normal fit. These standards ensure hardware compatibility and structural integrity, avoiding costly rework and enhancing overall performance.

Preventing Damage to Materials

Using a countersunk hole dimensions chart prevents material damage by ensuring correct hole sizing and angles. Oversized or improperly angled countersinks can cause stress concentrations, leading to material cracking or deformation. Incorrect pilot hole diameters may result in burrs or uneven screw seating, which can compromise structural integrity. Proper dimensions maintain even pressure distribution, avoiding excessive force during installation. This prevents surface damage and ensures screws sit flush, reducing the risk of material failure and enhancing overall durability and safety in engineering applications.

Key Dimensions in Countersunk Holes

Pilot hole diameter, countersink diameter, and angle are critical for proper screw fitment and material integrity, ensuring alignment and preventing damage. Charts provide precise measurements for accuracy and consistency in manufacturing processes.

Pilot Hole Diameter

The pilot hole diameter is the smallest diameter in a countersunk hole, drilled to guide the screw and ensure alignment. It must be slightly larger than the screw shank to prevent binding, typically by 0.05 to 0.1 mm for metric screws and 1/64 to 1/32 inch for imperial screws. Proper sizing ensures easy insertion and avoids damage to the material. Charts provide exact measurements for various screw sizes, making it easier to select the correct pilot hole diameter for specific applications, ensuring a precise and secure fit every time.

Countersink Diameter

The countersink diameter is the wider section of the hole that accommodates the screw head, allowing it to sit flush with the material surface. It is typically larger than the pilot hole and varies based on the screw size and desired fit. Using a countersunk hole dimensions chart ensures the correct diameter is selected for optimal performance. Proper sizing prevents issues like loose connections or material damage, ensuring a secure and flush fit for screws in various engineering applications.

Countersink Angle

The countersink angle determines the slope of the hole’s conical section and is critical for ensuring the screw head sits flush with the material surface. Standard angles are 90 degrees for metric fasteners and 82 degrees for imperial fasteners. Using a countersunk hole dimensions chart helps select the correct angle for specific screw types, ensuring proper seating and preventing damage. The angle must align with the screw’s head design to achieve a secure, flush fit without compromising material integrity or causing installation issues.

Types of Fits for Countersunk Holes

Countersunk holes are classified into close fit, normal fit, and loose fit, each catering to specific applications. Close fit ensures precision alignment, while loose fit allows for easier assembly.

Close Fit

A close fit is a precision alignment option for countersunk holes, requiring exact dimensional tolerances. It ensures minimal clearance between the screw head and the hole, providing stability and preventing movement. Ideal for high-stress applications, close fit minimizes wear and tear. Proper dimensions from the chart guarantee optimal performance. Tight tolerances must be maintained to avoid fitting issues. This fit is critical in aerospace and high-precision engineering. Improper dimensions can lead to poor alignment and potential failure. Always consult the chart for exact specifications.

- Minimal clearance for precise alignment.

- Used in high-stress and critical applications.

- Tight tolerances are essential for reliability.

Normal Fit

Normal fit is the most commonly used tolerance for countersunk holes, balancing precision and practicality. It provides adequate clearance for easy installation while maintaining sufficient stability. Ideal for general engineering applications, this fit minimizes production costs without compromising performance. Dimensions from the chart ensure proper alignment and functionality. Moderate tolerances accommodate minor variations, making it versatile for various materials and screws. Proper dimensions from the chart are essential for reliability. Normal fit is preferred for standard operations, offering a balance between cost and quality.

- Most common and versatile fit option.

- Balances precision and ease of assembly.

- Suitable for general engineering purposes.

Loose Fit

Loose fit provides the largest tolerance for countersunk holes, offering maximum flexibility during assembly. Ideal for applications requiring quick installation or where precise alignment is less critical. This fit is often used in construction, repairs, or with thicker materials. While it simplifies production, it may compromise stability and precision. Dimensions from the chart ensure sufficient clearance, accommodating minor irregularities. Loose fit is practical for scenarios where ease of assembly outweighs the need for tight tolerances. It remains a cost-effective solution for non-critical applications.

- Largest tolerance for easy assembly.

- Used in construction, repairs, and thick materials.

- Compromises stability for convenience.

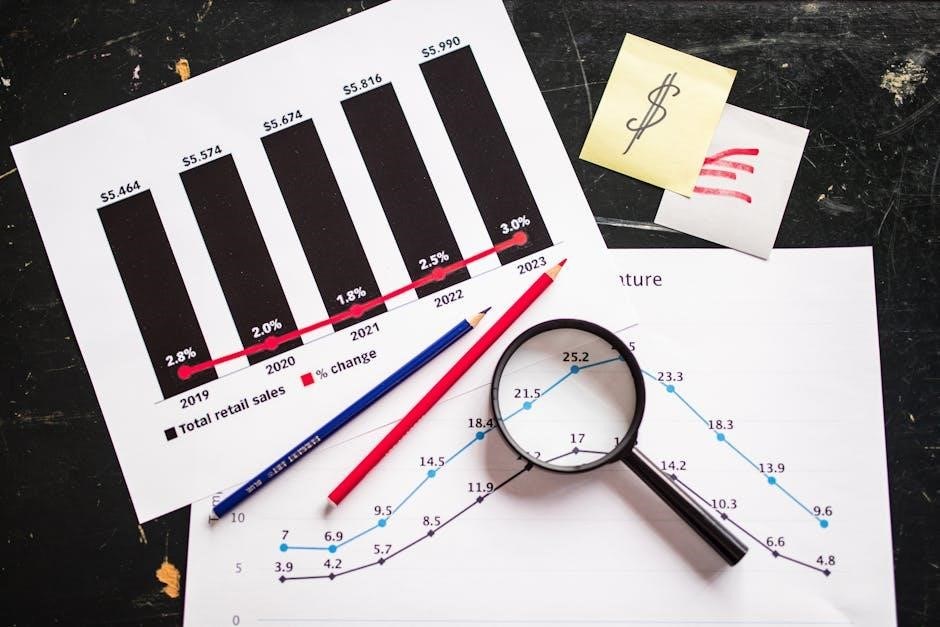

How to Read a Countersunk Hole Dimensions Chart

Understanding the layout is crucial for accurate dimensions. Identify screw types, hole sizes, and angles. Reference pilot hole diameter, countersink diameter, and angle for precise alignment. Use the chart to match screw sizes with correct hole dimensions, ensuring compatibility and fit. Pay attention to symbols and standards for accurate interpretation.

- Identify screw type and size.

- Reference pilot and countersink diameters.

- Check angles for compatibility.

Understanding Chart Layout

A countersunk hole dimensions chart is organized into columns and rows, with headers indicating screw types, sizes, and corresponding hole dimensions. typically, the chart lists screw diameters, pilot hole diameters, countersink diameters, and angles. Metric and imperial measurements are often included separately. The layout may also specify standards like ISO or ANSI. Each row corresponds to a specific screw size, making it easy to cross-reference dimensions. Symbols and abbreviations are defined to ensure clarity. The chart’s structure allows users to quickly find the required dimensions for their application, ensuring accuracy and efficiency in manufacturing processes.

- Identify screw type and size headers.

- Locate corresponding hole dimensions.

- Refer to standards for compliance.

Interpreting Dimensions for Screw Sizes

Countersunk hole charts provide precise measurements for specific screw sizes. Each screw type, such as flat-head or socket-head, corresponds to defined pilot hole, countersink diameter, and angle. For example, an ANSI Metric M4 screw requires a pilot hole of 4.5 mm and a countersink diameter of 9.4 mm. The chart ensures compatibility by matching screw dimensions to hole specifications. By aligning screw size with material thickness, users can achieve proper fit and prevent damage. Always refer to the chart for accurate measurements tailored to your screw type and application needs.

- Match screw type to hole dimensions.

- Consider material thickness for fit.

- Use gauges for precise hole alignment.

Standards and Specifications

ISO and ANSI standards regulate countersunk hole dimensions, ensuring compatibility and safety. ISO 7721 covers metric holes, while ANSI standards address imperial measurements, both specifying precise angles and diameters.

ISO Standards for Metric Holes

ISO standards provide precise specifications for metric countersunk holes, ensuring global consistency. They define dimensions like pilot hole diameters, countersink angles, and conical shapes for screws. Compliance with ISO 7721 guarantees compatibility with metric fasteners, ensuring proper fitment and functionality. These standards are crucial for manufacturers to maintain quality and reliability in their products, especially in international markets where uniformity is essential. By adhering to ISO guidelines, professionals can avoid installation issues and ensure optimal performance across various applications.

ANSI Standards for Imperial Holes

ANSI standards provide detailed specifications for imperial countersunk holes, ensuring consistency in U.S. customary units. These standards define dimensions such as pilot hole diameters, countersink angles, and hole depths for screws. For example, an ANSI Inch 1/2 flat head screw requires a pilot hole diameter of 9/16″, a countersink diameter of 1″, and an 82-degree angle. Compliance with ANSI standards ensures compatibility with imperial fasteners, maintaining proper fitment and functionality. These guidelines are essential for manufacturers to achieve precision and reliability in their products, particularly in regions using imperial measurements.

Design Considerations

Material thickness and screw selection are critical for proper countersink design. The countersink angle impacts hardware seating, with metric requiring 90° and imperial typically 82°. Both ensure flush alignment.

Material Thickness and Screw Selection

Material thickness significantly impacts countersink design. Adequate thickness ensures the screw head sits flush without compromising structural integrity. Thinner materials require shallower countersinks. Screw selection is crucial, as flat-head screws need precise pilot hole diameters to prevent pull-through. The countersink angle must align with the screw head type, typically 90° for metric and 82° for imperial fasteners. Incorrect sizing can lead to material damage or improper seating. Always consult the countersunk hole dimensions chart for specific screw and material combinations to ensure optimal results and durability.

Affect of Countersink Angle on Hardware

The countersink angle directly impacts hardware compatibility and functionality. A 90° angle is standard for metric fasteners, while an 82° angle suits imperial hardware. Proper alignment ensures the screw head sits flush, preventing uneven surfaces. An incorrect angle can lead to poor fit, reduced strength, or hardware malfunction. Always refer to the countersunk hole dimensions chart to match the angle with the specified screw type, ensuring optimal performance and longevity of the assembly.

Tools and Gauges for Countersinking

Specialized tools are essential for creating precise countersunk holes, including drill bits, countersink cutters, and depth gauges, ensuring accurate hole creation and proper screw seating. Referencing a countersunk hole dimensions chart helps in selecting the right tools for specific screw sizes and materials.

Specialized Drill Bits and Cutters

Specialized drill bits and cutters, such as spade bits or Forstner bits, are designed for creating countersunk holes. These tools ensure precise pilot holes and conical shapes. Using the correct cutter size, as specified in a countersunk hole dimensions chart, guarantees accurate hole diameters and angles. Proper tool selection prevents material damage and ensures smooth screw installation. Always refer to the chart for tool sizing to match specific screw dimensions and material thickness, ensuring optimal results in metal or plastic applications.

Using Depth Gauges for Accuracy

Depth gauges are essential for achieving precise countersunk hole depths. They set a specific maximum depth below the surface, ensuring consistent measurements. This tool is particularly useful for maintaining accuracy across multiple holes. By referencing a countersunk hole dimensions chart, gauges can be calibrated to match required specifications. Proper setup ensures depths are controlled within tight tolerances, typically ±0.005 inches. This level of precision is critical for avoiding material damage and ensuring screws fit correctly. Using depth gauges enhances the reliability of countersinking operations in both manual and automated processes.

Creating a Countersunk Hole Dimensions Chart

Developing a countersunk hole chart involves organizing screw sizes, pilot hole diameters, countersink diameters, and angles. Reference standards like ISO and ANSI for accurate, standardized dimensions.

Steps to Develop a Custom Chart

To create a custom countersunk hole chart, start by identifying the specific screw sizes and types needed. Refer to ISO or ANSI standards for baseline dimensions. Measure pilot hole diameters, countersink diameters, and angles for each screw size. Organize the data into a table, ensuring clarity and readability. Include tolerance ranges for accuracy. Verify measurements with precision tools to maintain consistency. Finally, customize the chart for material thickness and specific application requirements, ensuring it meets engineering standards for reliability and performance.

Calculating Dimensions for Specific Screws

To calculate dimensions for specific screws, measure the screw head diameter and required depth. Refer to ISO or ANSI standards for baseline dimensions. Use a countersunk hole chart to find the pilot hole diameter, countersink diameter, and angle for the screw size. Apply the desired fit type (close, normal, or loose) to determine tolerances. Ensure the countersink angle matches the screw head (90° for metric, 82° for imperial). Verify dimensions with precision tools to avoid installation issues like loose joints or material damage.

Common Mistakes to Avoid

Common errors include misaligned pilot holes, incorrect countersink angles, and improper tool selection. Always verify screw size compatibility and material thickness to ensure accurate hole dimensions.

Incorrect Hole Diameter

Using an incorrect hole diameter is a common mistake that can lead to improper fit and alignment of screws. This can result in a loose fit, causing the screw head to sit too high or potentially pull through the material. To avoid this, always refer to a countersunk hole dimensions chart, which provides precise measurements for pilot hole and countersink diameters based on screw size. For example, an ANSI Metric M4 machine screw requires a pilot hole of 4.5 mm, while an ANSI Inch 1/2″ flat head screw needs a pilot hole of 9/16″. Using the correct diameter ensures a flush finish and prevents material damage. Proper alignment and fit are critical for structural integrity and safety in engineering applications.

Improper Countersink Angle

An incorrect countersink angle can lead to screws not seating properly, resulting in a protruding head or uneven surface. The standard angle for metric holes is 90 degrees, while imperial holes typically use 82 degrees. Using the wrong angle can cause the screw head to sit too high or low, compromising the flush finish. This mismatch can also weaken the joint’s structural integrity. Always consult a countersunk hole dimensions chart to ensure the correct angle for your specific screw type, preventing installation errors and ensuring optimal performance and safety in engineering applications.

Countersunk hole charts are essential for precise hole dimensions, ensuring proper fit and alignment while preventing installation errors and damage to materials.

Countersunk hole dimension charts are crucial for ensuring proper fit, alignment, and material integrity. Key dimensions include pilot hole diameter, countersink diameter, and angle, with metric and imperial standards applying. Normal, close, and loose fits dictate sizing, while ISO and ANSI standards guide specifications. Tools like specialized drill bits and depth gauges enhance accuracy. Common mistakes, such as incorrect diameters or angles, can lead to installation issues. Using charts prevents errors, ensuring optimal hardware performance and material durability in engineering applications.